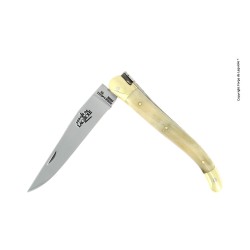

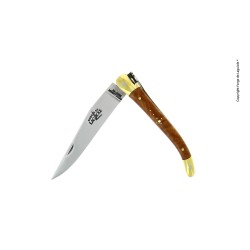

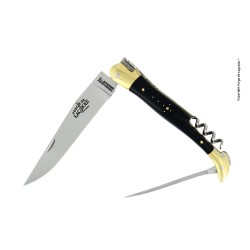

List of products by brand FORGE DE LAGUIOLE

Knife factory that manufactures its knives in Laguiole according to a cutlery tradition dating back to 1828.

A real journey back in time in the heart of the village of Laguiole, a hundred employees work daily to perpetuate the cutlery tradition within the Forge de Laguiole® factory.

Exuding a particular energy, the village of Laguiole is the ideal melting pot, which inspires our cutlers day after day.

Each Forge de Laguiole knife bears the signature of our cutlers. The quality of our knives is an expression of the power and beauty of our landscapes and our remarkable environment.

The blades are forged 1000° in our manufacture from a French steel produced exclusively for Forge de Laguiole®.

The result of a skilful dosage of carbon and chromium, this steel ensures an exceptional sharpness, excellent cutting durability and remarkable ease of sharpening while guaranteeing inalterability of the blade.

The steels used in cutlery are mainly martensitic stainless steels. These steels are very hard and consist of a high percentage of chromium, carbon and other elements that have interesting properties (molybdenum, vanadium...).Knife blades must sharpen easily, have good machinability and have a good cut hold. These properties cannot be obtained simultaneously, so a compromise must be found depending on the use of the knife. To obtain the hard structure called martensite, the blade must undergo an appropriate heat treatment (annealing, quenching, tempering...) .

The choice of steel is a compromise between:

The ease of sharpening the blade

The cutting edge of the blade and its hold over time

Its ability to resist corrosion

Its ability to be polished and its resistance to stripes

To the manufacture, we have added two criteria which are:

Its French origin exclusiv

All metal parts for the design of Forge de Laguiole® knives are manufactured within the forge.

Our T12 steel is a French steel hot-rolled by the Bonpertuis Steelworks (near Grenoble). This steel is an alternative between carbon steel and all-stainless steel. It has a good balance between carbon and chromium. It is structured in very fine grains, which guarantees excellent cutting quality, durability and good resistance to oxidation.

Steel must meet very strict criteria:

Excellent cut

Abrasion wear resistance

Easy sharpening and polishing.

Good resistance to oxidation.

All the miters are hot forged in our workshops and then welded on the plates which will be drilled and polished before assembly. Our massive miters can be made of stainless steel or brass. They protect the ends of the handle from everyday use.

The handles made of wood, horn, bone, or even mammoth molar, are chosen, carved and set by hand by our cutlers.